*Industry Knowledge Development*A

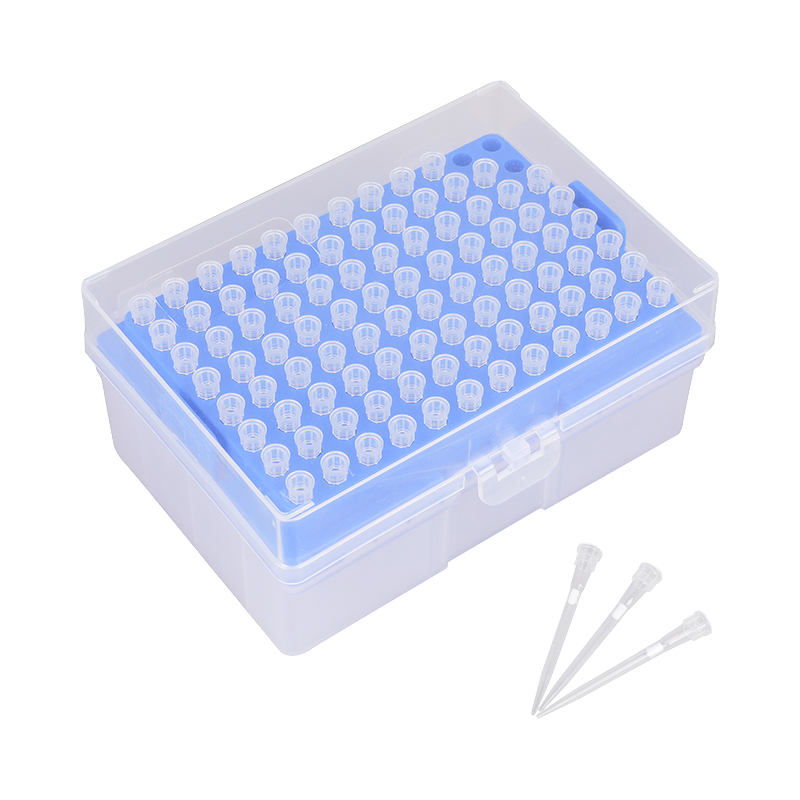

plastic centrifuge tube, also known as a centrifuge vial or tube, is a laboratory instrument used in the separation and analysis of biological samples through centrifugation. It is commonly made of a transparent or translucent plastic material, such as polypropylene or polycarbonate, which allows for easy observation of the sample.

Here are some key features and uses of plastic centrifuge tubes:

1.Material: Plastic centrifuge tubes are typically made of durable and chemical-resistant plastics like polypropylene, which ensures they can withstand high speeds and various chemical solutions used in laboratory processes.

2.Capacity: They come in different sizes and capacities, ranging from a few milliliters to several tens of milliliters. The most common sizes are 15 mL and 50 mL tubes, but smaller capacities are also available for specific applications.

3.Conical Shape: Most plastic centrifuge tubes have a conical shape, which facilitates the collection of the separated sample at the bottom of the tube after centrifugation. The tapered design also aids in efficient pellet formation during centrifugation.

4.Graduations and Labels: Many centrifuge tubes have volume graduations marked on the side, allowing precise measurement of the sample. Some tubes also provide areas for labeling, which is useful for sample identification and organization.

5.Sealing: Plastic centrifuge tubes can be sealed using various methods, such as snap caps, screw caps, or plug-seal caps. This helps to prevent sample leakage or contamination during centrifugation or storage.

6.Compatibility: Plastic centrifuge tubes are compatible with most laboratory centrifuges. However, it's essential to check the manufacturer's instructions or guidelines to ensure they are suitable for use with specific centrifuge models and maximum recommended speeds.

7.Applications: Plastic centrifuge tubes are widely used in molecular biology, biochemistry, clinical diagnostics, and other research and diagnostic applications. They are commonly employed for sample preparation, cell culture, DNA/RNA isolation, protein separation, and other centrifugation-based techniques.

It's important to note that plastic centrifuge tubes are disposable and are typically discarded after a single use to prevent cross-contamination between samples. Proper disposal methods should be followed according to local regulations and laboratory protocols.

Plastic centrifuge tubes are commonly used in laboratory settings for various purposes, such as sample preparation, separation, and storage. The cleanliness and hygiene of these tubes depend on several factors:

1.Manufacturing: High-quality plastic centrifuge tubes undergo strict manufacturing processes, including molding and sterilization, to ensure they are clean and free from contaminants when they leave the factory.

2.Sterilization: Before use, plastic centrifuge tubes are often sterilized using methods like autoclaving, gamma irradiation, or ethylene oxide treatment. These processes effectively kill or remove microorganisms, ensuring a sterile environment for the samples.

3.Handling: Proper handling practices are essential to maintain the cleanliness of the centrifuge tubes. Lab personnel should wear gloves and take precautions to prevent contamination during sample collection, transfer, and storage.

4.Storage: Centrifuge tubes should be stored in clean, dry areas, preferably in sealed bags or containers to protect them from dust, moisture, and other contaminants. Proper storage practices help maintain the tubes' hygiene until they are ready for use.

It's important to note that while plastic centrifuge tubes are designed to be clean and hygienic, it's still crucial to follow good laboratory practices to minimize the risk of contamination. Regular cleaning, sterilization, and proper disposal of used tubes are essential for maintaining a hygienic environment in the laboratory.

English

English Español

Español

Contact Us

Contact Us