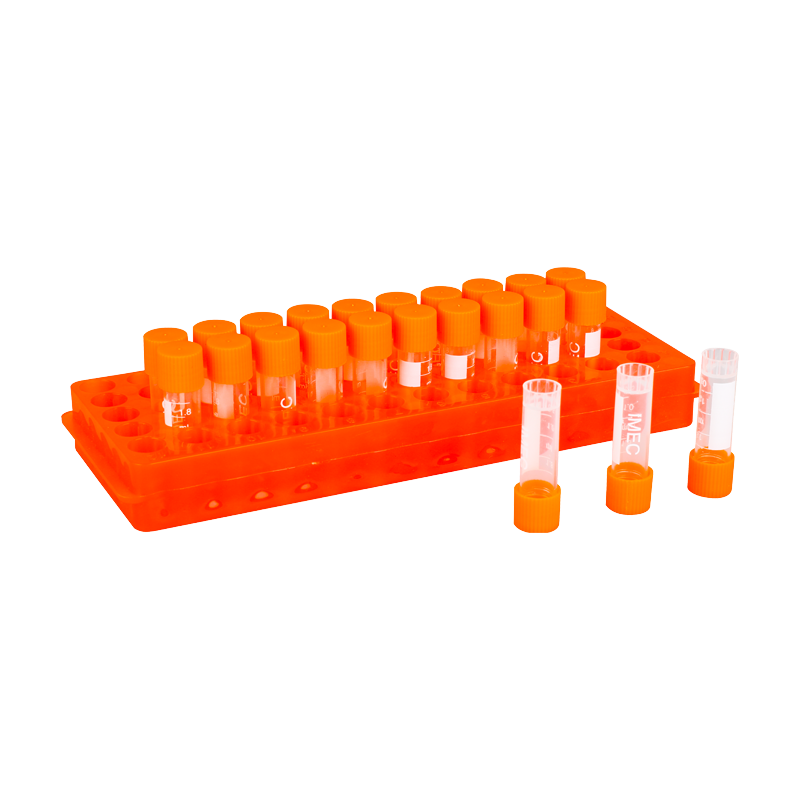

*Industry Knowledge Development*A plastic cryovial tube, also known as a cryogenic vial or cryotube, is a specialized type of plastic tube designed to store biological samples, such as cells, tissues, or other biological materials, at extremely low temperatures. These tubes are commonly used in various fields, including biomedical research, clinical laboratories, and cryopreservation.

Here are some key features and characteristics of

plastic cryovial tubes:

1.Material: Plastic cryovial tubes are typically made from high-quality, durable materials such as polypropylene or polyethylene. These materials are chosen for their excellent resistance to low temperatures and their ability to withstand the freezing and thawing cycles involved in cryopreservation.

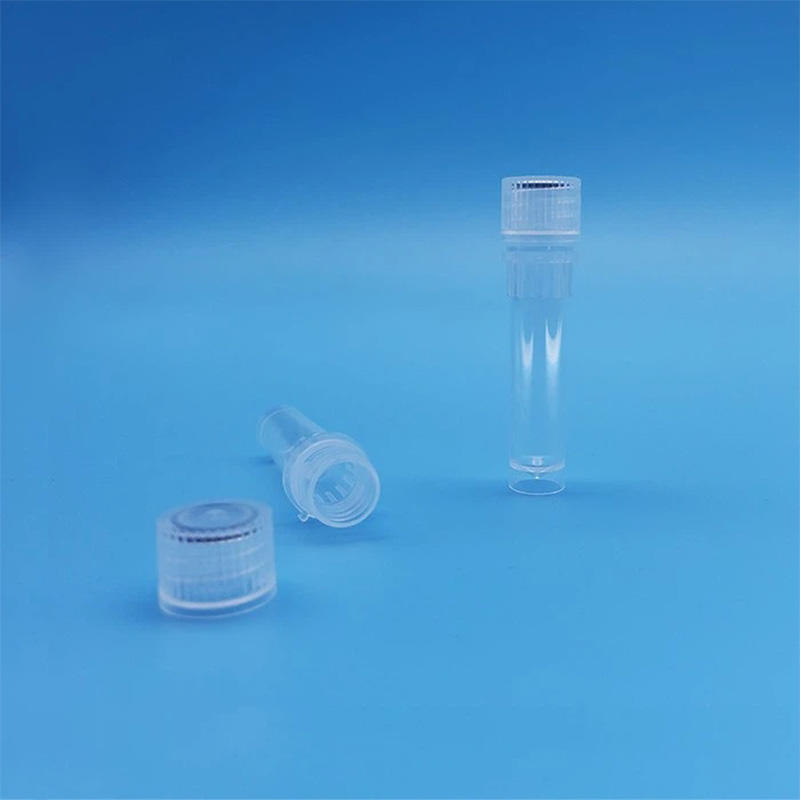

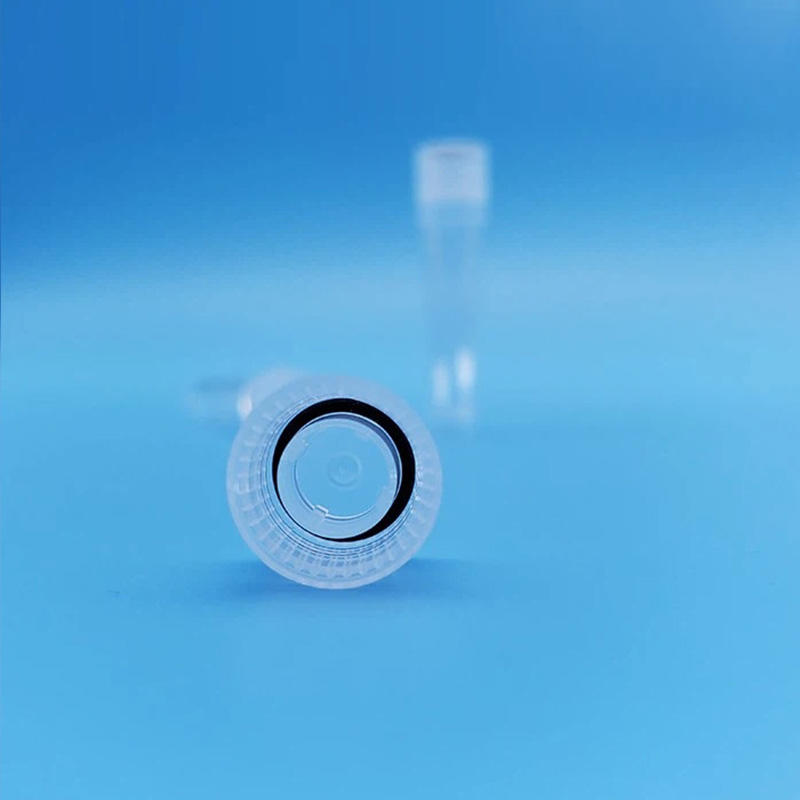

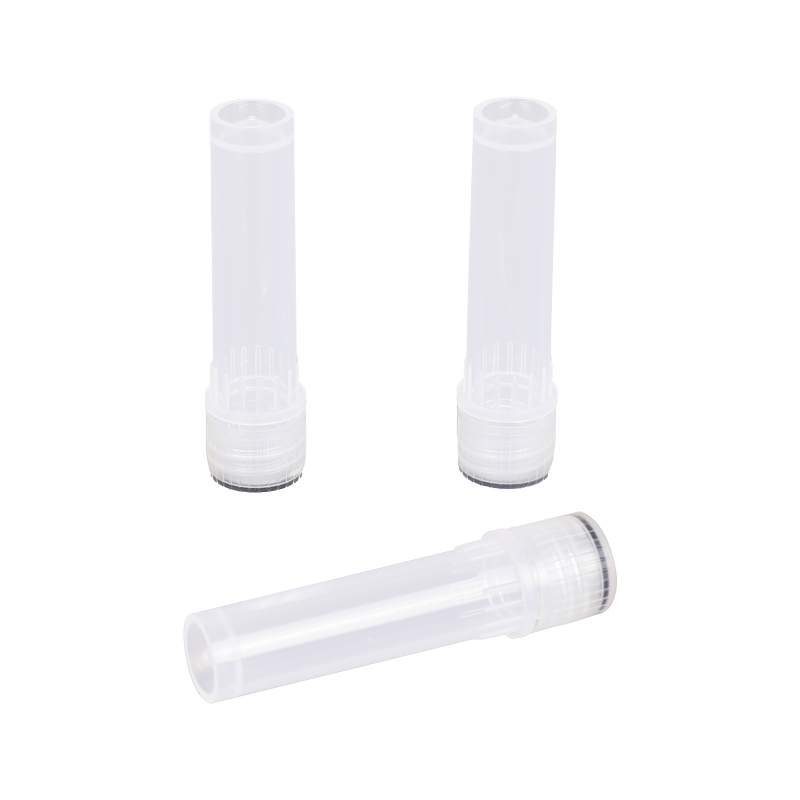

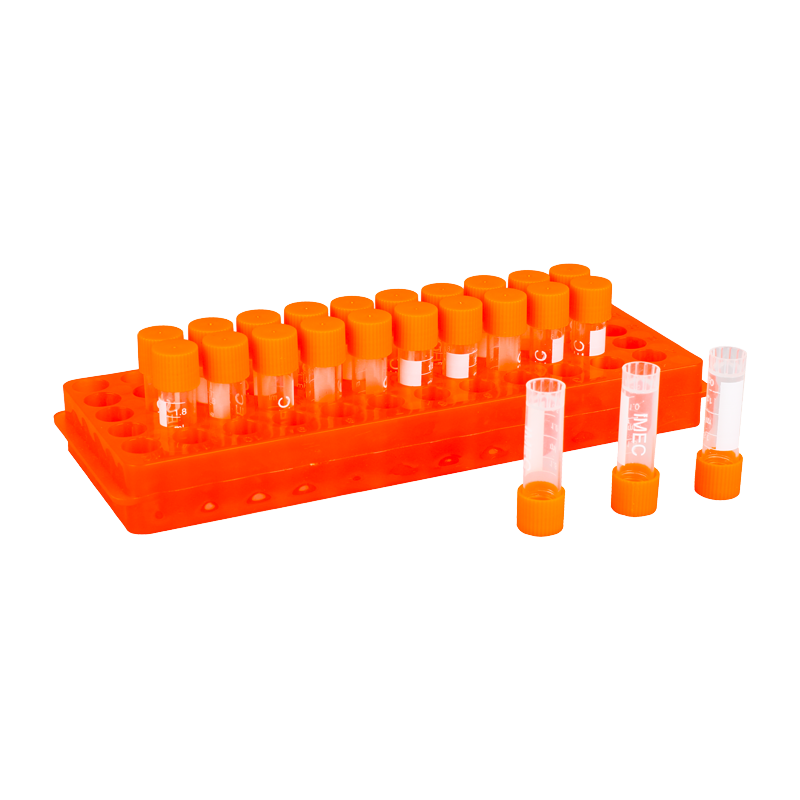

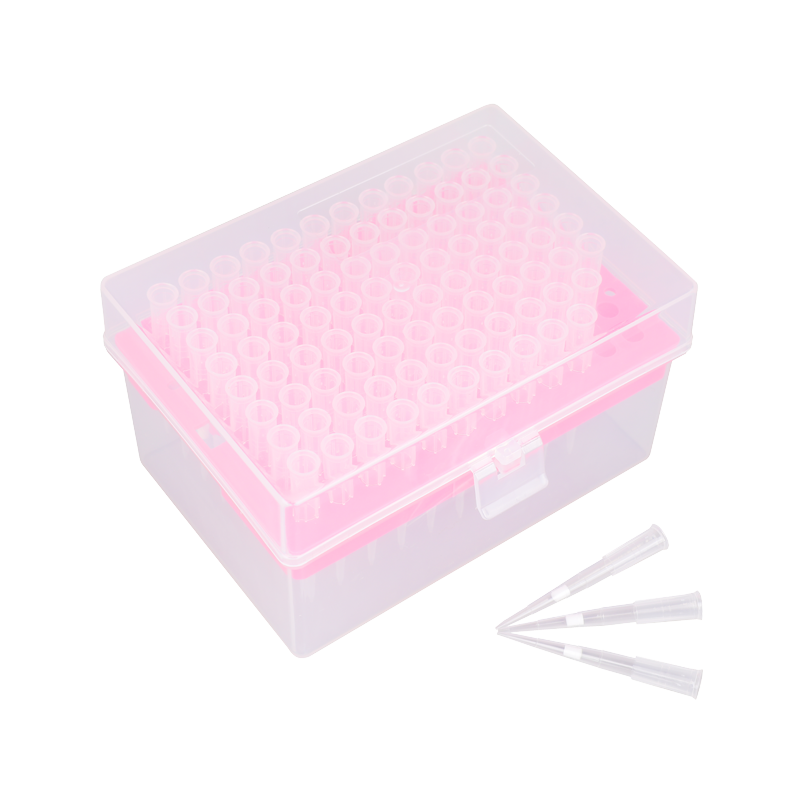

2.Screw-cap design: Cryovial tubes usually have a screw-cap design to ensure a secure and leak-proof seal. The cap is threaded to the tube, providing a tight closure that prevents the entry of contaminants and minimizes the risk of sample loss or contamination during storage.

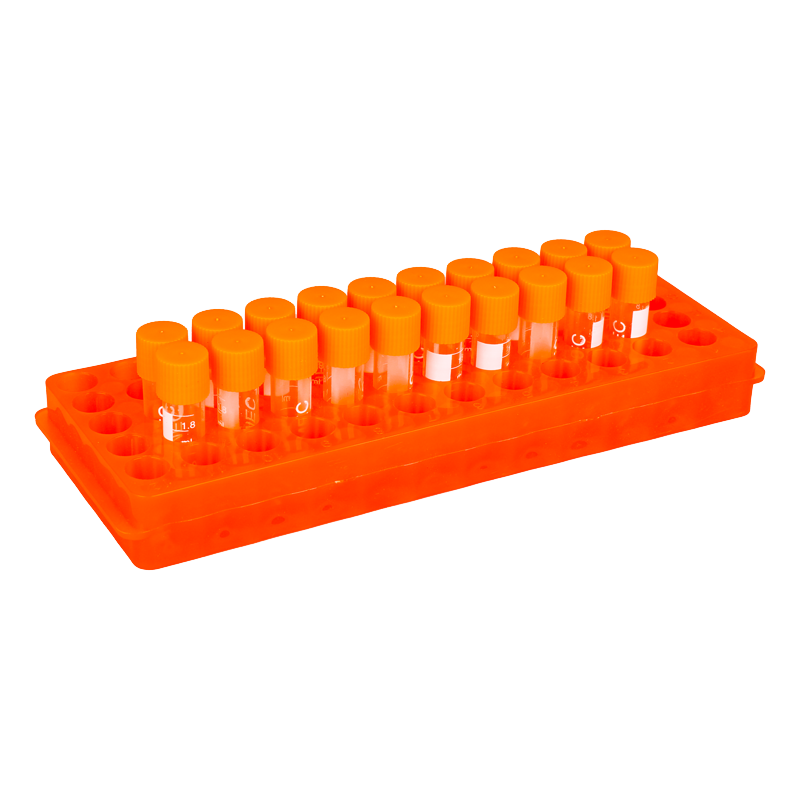

3.Graduations and labeling area: Many cryovial tubes come with graduations or volume markings on the side, allowing for accurate sample measurement and easy identification of sample volumes. Additionally, there is often a designated area on the tube or cap for convenient sample labeling, ensuring proper sample identification.

4.Cryogenic compatibility: Plastic cryovial tubes are designed to withstand extremely low temperatures, typically ranging from -80°C to -196°C (-112°F to -321°F). This makes them suitable for long-term storage in ultra-low temperature freezers or in liquid nitrogen storage systems.

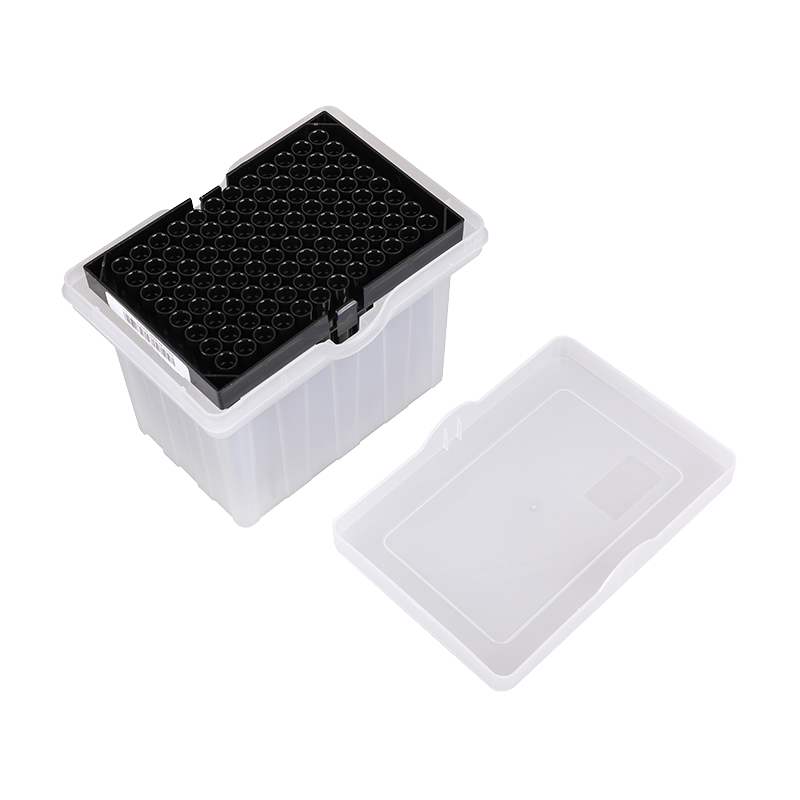

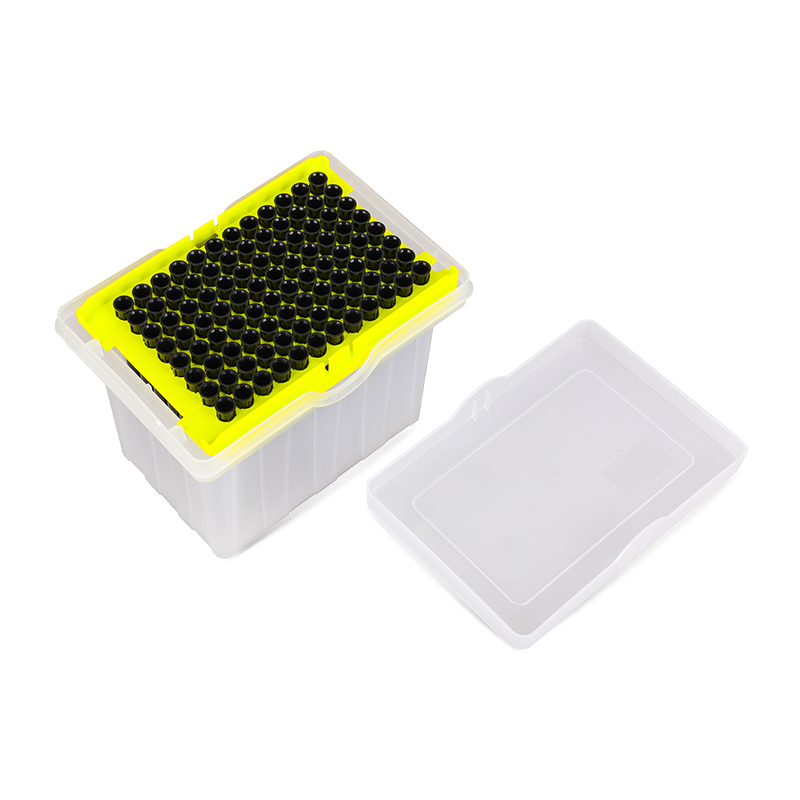

5.Sterility: Cryovial tubes are commonly available in sterile formats, ensuring that the samples stored inside remain uncontaminated. Sterility is particularly crucial for applications involving cell culture or sensitive biological materials.

6.Variety of sizes: Plastic cryovial tubes come in a range of sizes, including standard volumes such as 1.5 mL, 2 mL, and 5 mL. This allows researchers to choose the appropriate size based on their sample requirements and storage needs.

When choosing a plastic cryovial tube, there are several factors to consider to ensure that it meets your specific requirements. Here are some key considerations:

1.Material: Plastic cryovial tubes are typically made of materials such as polypropylene or polycarbonate. Polypropylene is widely used due to its excellent chemical resistance and low protein binding properties. Polycarbonate tubes offer higher impact resistance but may be more expensive.

2.Capacity: Determine the volume of your sample and choose a cryovial tube with an appropriate capacity. Cryovial tubes come in various sizes, typically ranging from 0.5 mL to 5 mL or more.

3.Closure type: Consider the closure mechanism of the cryovial tube. Common closure options include screw caps, snap caps, or push-on caps. Screw caps offer a secure seal but may require more time for opening and closing. Snap caps provide quicker access but may be less secure for long-term storage.

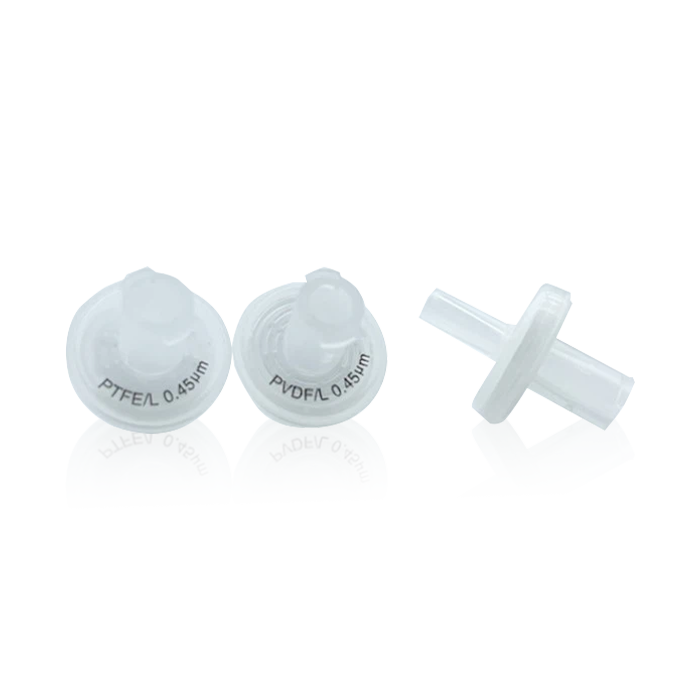

4.O-ring or silicone gasket: Some cryovial tubes have an O-ring or silicone gasket seal to enhance the tightness of the closure and minimize the risk of sample leakage during storage. If you require a higher level of sealing, consider tubes with this feature.

5.Compatibility: Ensure that the cryovial tube is compatible with your storage conditions. Check if it can withstand the temperature range required for your specific application, such as ultra-low temperature storage or cryogenic conditions.

6.Sterility: Depending on your application, you may require cryovial tubes that are pre-sterilized. Sterile tubes are essential when working with sensitive biological samples to prevent contamination.

7.Graduations and labeling: Consider whether you need cryovial tubes with graduated markings for accurate sample measurement. Additionally, some tubes have areas designated for labeling, which can be useful for sample identification.

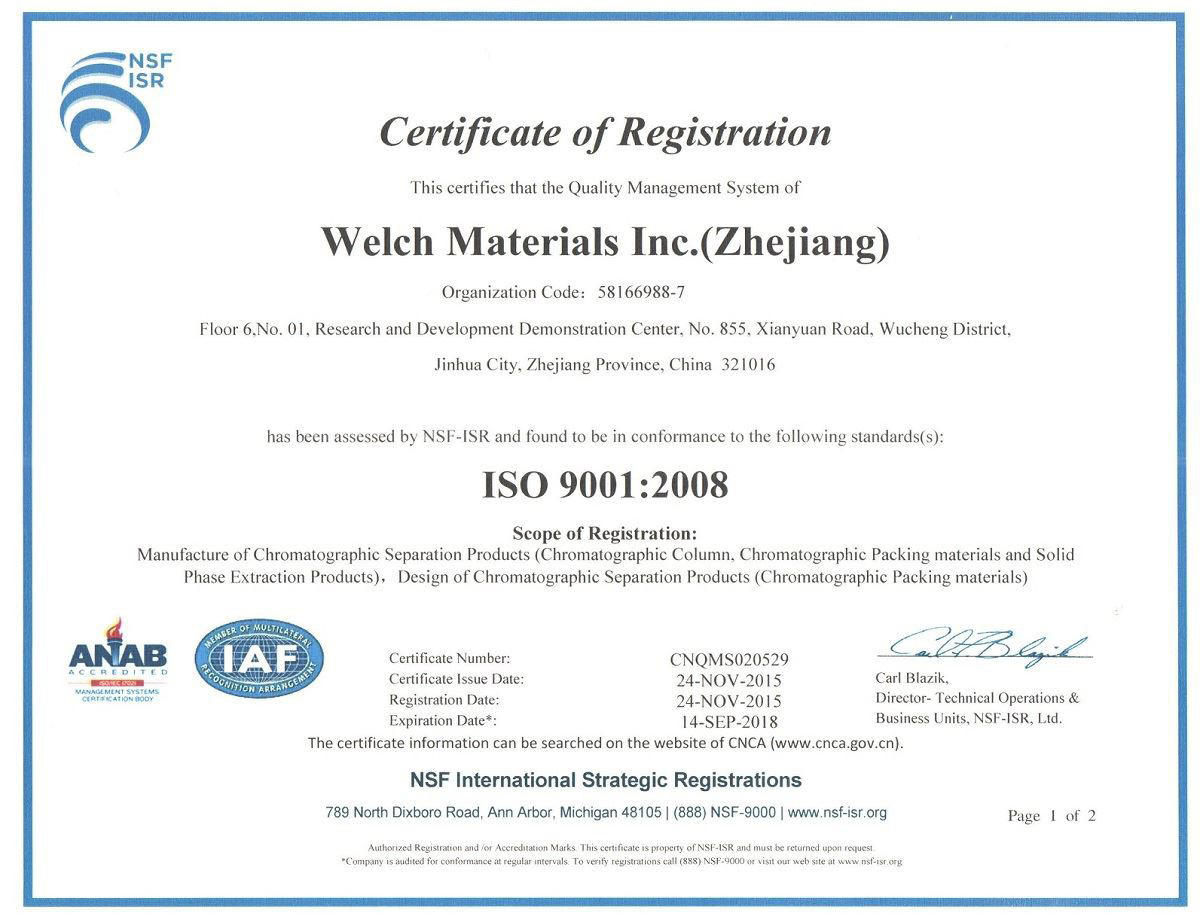

8.Supplier reputation: Choose reputable suppliers or manufacturers known for producing high-quality cryovial tubes. Read reviews or seek recommendations from other researchers to ensure the reliability and performance of the tubes.

Remember to evaluate your specific needs, such as the type of samples, storage conditions, and intended applications, when selecting plastic cryovial tubes.

English

English Español

Español

Contact Us

Contact Us